Yesterday my fiber buddy and I went up to Orland, about three hours' drive to the north, to observe/participate in a sheep shearing. Shearing for spinners is different from shearing a meat flock, because the quality of the fleece really, really matters. Also, this were Cormo sheep -- a cross that includes Merino -- and they have wrinkly, delicate skin. There are inevitable nicks and scrapes to be dealt with.

I spent most of the day doing animal handling -- that's pretty interesting to me and it seemed like they had plenty of people to deal with the fleeces -- and she spent the day dealing with the fleeces.

I've put my (numerous) photos after the cut, and I'm still editing the video I shot.

Let's start with animal handling, since that was what I was doing.

The sheep were penned on one side of the shearing barn, and the shearing happened on the other side. Here's Phantom and her baby, born only a few days ago, waiting in a special mommy pen. Beside her are the white sheep that will be sheared. Behind her are sheep that will not be sheared on this day (the process goes slowly enough that it has to be done over several days. So you, too, can participate in a shearing in Orland!).

The process starts with moving some sheep from the holding pen to the shearing pen, down a little temporary chute.

We worked on coloured sheep in the morning, then whites in the afternoon. Here are the sheep waiting for shearing when we arrived in the morning:

And the line of sheep in the afternoon. The separation is mainly to make it easier to keep the white fleeces from getting bits of grey or black fleece in them, or vice versa. I've mixed up the images in this post in order to choose the better shots to tell the story.

The shearing itself was done by a professional shearer. He uses a trapeze thing to help him keep his balance and save his back while wrangling heavy sheep around. He starts by removing the wool that won't be part of the fleece: the stuff from the belly and butt, which is caked with sheep poop and stuffed with foxtails and other junk from being dragged around through pastures all year.

(See the heads back there? That's where the fleeces were being handled.)

When that stuff has been swept away, he quickly and efficiently removes the fleece all in one sheet. A good fleece will kind of stick together in a blanket.

As you can see, the sheep are totally complacent during the process. Once sheep are on their backs they go completely still and let themselves be handled, which is pretty handy for the shearer (and safer for the sheep).

After the sheep were sheared, they went into a little pen to be processed. Here we have an unsheared sheep (right) looking in on the sheared sheep (left).

In the little pen, I picked the foxtails out of the sheep's skin, picked them out of their noses and the odd little ducts by their eyes, cleaned out their ears and basically made sure they would not be poked by chunks of stuff in their coats for the whole year. This meant that by the end of the day my hands were covered in lanolin; it took four washes to get the thick layer of oil off my hands.

Once they were picked clean-ish, the shepherd vaccinated them (different vaccines for year-olds and adults), then she sprayed them with bug spray to keep lice off them.

Then they got new coats, an elaborate fitting process, because the coat needs to be large enough to accommodate their future fleece, while small enough that it won't drag and get pulled off before the next shearing.

After that they got to go out into a nearby pen to be observed for adverse vaccine reactions and have something to eat (they'd had to fast so they wouldn't poop during shearing).

On the fleece side, events began before the shearing was even finished. As the sheep was being sheared, the shearer would take a hunk of wool from the shoulder and hand it over the wall to be saved as a sample. Those were labeled with the sheep's tag number and stored in this box:

Once the fleece was off the sheep and the sheep moved on to the next stage, the sheared fleece was bundled carefully in a sheet and handed over the wall of the shearing pen. It was immediately weighed for raw weight:

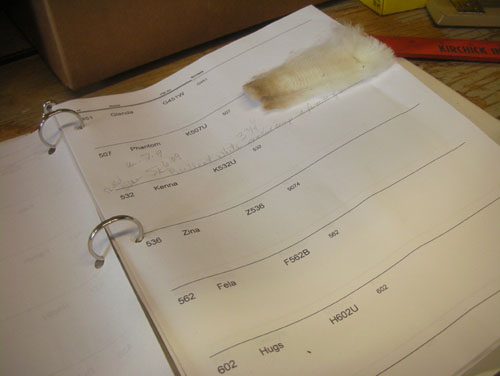

That weight was recorded in this book, along with a sample lock of wool, the final skirted weight, plus some comments on the fleece from the people doing the handling.

Then it was time to lay the fleece out for skirting. Skirting is the process of removing bad or unusable bits of the fleece, so that a spinner who buys the fleece knows the weight of the fleece she's buying is the weight of total usable wool. Unskirted fleeces should cost less per pound, because there's more wool in them that is not usable (due to felting, gunking up with poop, or excessive vegetal matter).

Each fleece was oriented with its head end toward the door, so they were all lined up the same way, then the sheet was removed.

Then the fleece was gently shaken to knock out the second cuts (places where there were very short pieces of wool from a second pass with the shearing clippers) and any loose pieces of junk in there.

Here's an adult fleece laid out over the table. With this set of sheep, we were lucky to see a fleece this large; most were half this size. I think this one ended up being about 6 lbs altogether.

This year, the shepherd had a huge problem with foxtails in the hay; the seeds were in the hay, then the foxtails sprouted in the pasture, and there were foxtails everywhere. So we went over the fleeces, pulling out as many foxtails as possible.

The fleeces were gorgeous.

Not so gorgeous was the junk that fell off the table. As the day went on, the pile of junky bits grew. Better on the floor than in the fleece, of course.

When the fleece was skirted and cleaned up, we rolled it with paper to keep it from jumbling together. This way, the fleece can be unrolled and laid out in the shape of the sheep again.

It took a couple of people to roll the fleece up like this, going carefully to keep from pulling the fleece apart.

The rolled fleece was then itself rolled in more paper:

And tied into a neat bundle:

Which was labeled the the sheep's tag number and a few other small notes.

Then carried off into the wool room for storage. This is the wool room after two fleeces had been sheared, quite early in the morning:

And this is the wool room at the end of the day:

But there's more! One of the sheep had figured out how to open the gates and so a couple of the ladies (like the afore-pictured Phantom) had babies in tow. This is little Henry, Hester's baby. (Maybe he should be Harry with that lightning streak on his face.) He's a couple days old.

He was mostly with us in the post-shearing processing area, and sometimes he curled up and fell asleep in the most odd places.

And this is Joe, who is INSANE, like all Border Collies. Joe was not allowed in to the barn, for reasons that are probably pretty obvious.

Yes, I did kick his ball for him. I'm not cruel to animals or anything.