A couple weekends ago I took a two-day class on silk reeling with the Southern California Handweavers' Guild. The teacher was the inimitable Michael Cook. It's hard to write about a class like this because 1) Michael has already written quite a bit about reeling, much more than I could, and 2) a lot of what I learned was physical rather than intellectual. I can't show you how to flick your wrist just right to catch the ends of a silk cocoon in this post.

So this is going to be more about my impressions of the class than a post that could get you started on reeling yourself.

First, the equipment. Michael brought some hand reels -- the squat ones are from Japan, and the tall narrow one is made by Alden Amos. A silk reel should let a lot of air in, so the wet silk doesn't stick to the reel and make a mess.

He also brought a couple of Zakuris -- Japanese silk reel winders.

The mechanical zakuri was by far the easiest way to reel silk, but of course (of course!) zakuris are pretty much impossible to get; there is no US maker or supplier. (One side panel of this zakuri was taken off for some reason, but usually the reel is supported on both sides.)

That's the zakuri reel, once filled up.

Some of the other tools are very simple household tools, like a little scrub bob to pick up the ends of the cocoons from the bath:

And this very simple thread guide that we used several times while winding off of reels or bobbins:

A pair of tongs keeps your fingers from burning as you push the cocoons back into the pot.

The most obscure and unusual piece of equipment was one Michael made himself, the croissure, made of copper pipe, pulleys, and some specialized fiber handling parts. This is one configuration for the setup, for Laotian-style reeling (results in a slubbier thread).

The Chinese or Japanese style reeling, which produces a more even thread, uses a taller croissure.

The X in the thread there serves to squeeze water out of the silk and press it together; as you ran the silk through the croissure a fine spray of water flies off, looking a bit like steam.

OK, that said, some photos of the process.

We started on Saturday with Laotian reeling, which is simpler and produces a slubbier thread. I found it more sympatico, I admit.

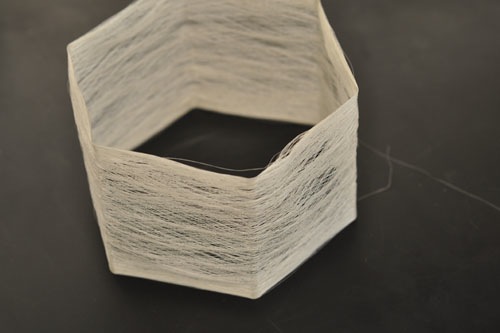

There's my Laotian-style thread wound onto a reel and tied up to secure it for the degumming bath.

And the same skein, slid off the reel.

Another reel of thread, just to show you how stiff the silk can be before the gum is removed. The seracin is actually used to stiffen fabrics like organdy or to make stiff lamp covers.

Can you see those tiny strands of silk going into the eye? Those are each a single thread from a single cocoon.

Laying out the thread is a characteristic of Laotian reeling.

At the center of each cocoon is a dead silkworm.

The finished product, not yet degummed.

A pile of bobbins. We each got one to take home our reeled silk. Mine is hopelessly tangled.

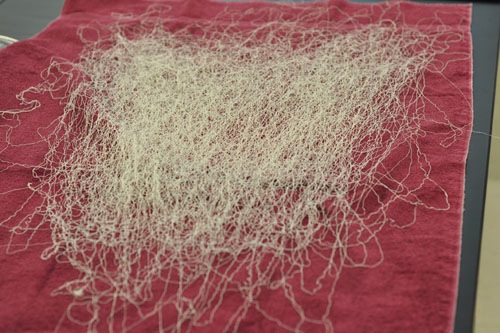

If you don't want stiff silk, you need to put the skeins through a degumming bath. This is basically boiling it in soap, though there is obviously a bit more to it than that.

The handful of class skeins about to be degummed. It makes sense to degum a bunch of silk at once, as it's as much work to degum one skein as it is fifteen.

My skein, after degumming. It felt more like what we think of as silk. With handling and showing it off, the skein has gotten pretty badly tangled up.

And one of my take-homes. A little packet of silkworm eggs, lying on a mulberry leaf. I have no idea if they're doing OK, because I think it might be a little cold in our pantry for them. But it seemed worth a try.